Differences between Peribest peristaltic pumps and helicoidal pumps

Progressive cavity pumps are highly resistant to abrasion, as there is no metal-to-metal contact as occurs in gear or lobe pumps, nor do they operate at high speeds, like centrifugal pumps. this makes them very suitable for pumping abrasive products.

However, they have a number of limitations:

- In some applications with highly abrasive products, the life of the progressive cavity pump’s stator and rotor is limited, due to the high friction between the metal rotor and the rubber stator.

- In applications where the product polymerises or plasticises on contact with air (such as latex, for example), sealing problems may occur in the mechanical seals.

- They cannot rotate dry. The pumped product lubricates the area between the pump’s stator and rotor. If there is no product in the pump, the stator is damaged immediately.

- There are many metal parts, which makes it complicated and costly to make a version capable of pumping corrosive products.

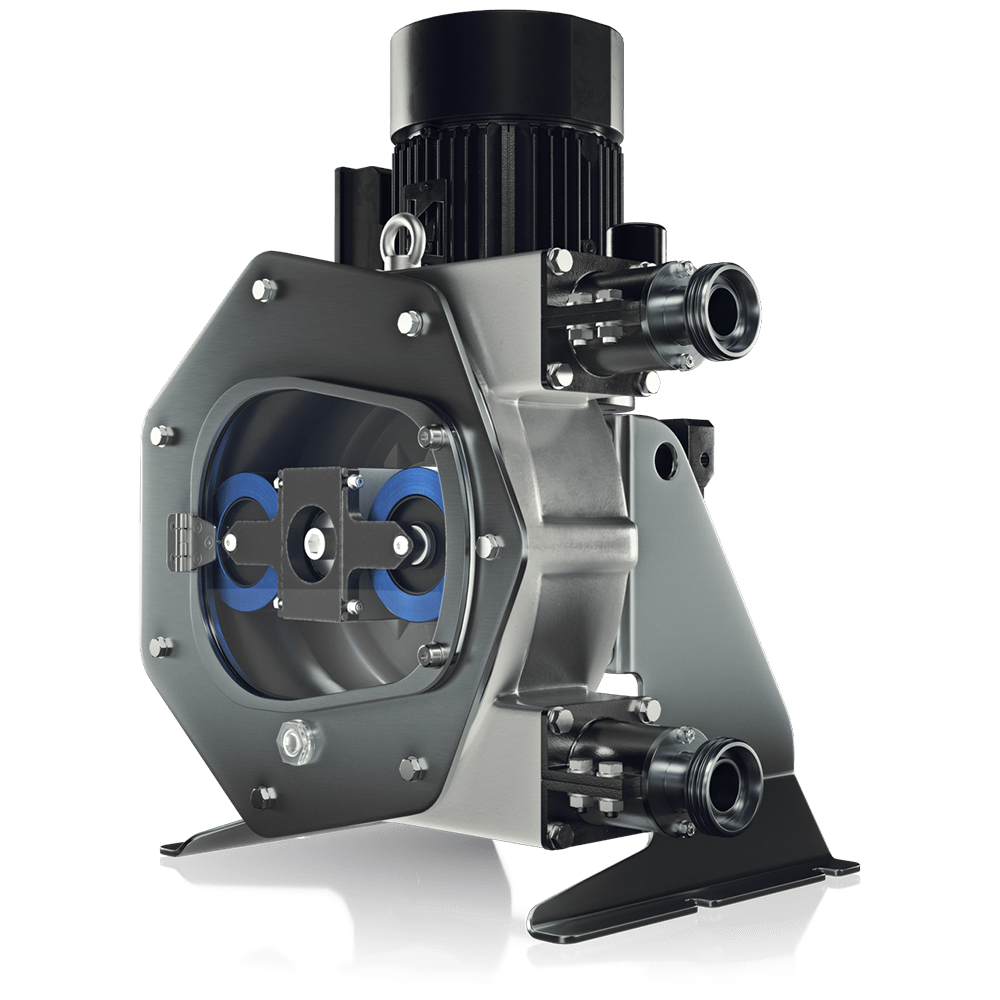

For applications where the progressive cavity pump has these limitations, a good solution is to use the PeriBest industrial peristaltic pumps. The main advantages are:

- The PeriBest pumps do not have any moving parts in contact with the product. Thus, abrasive product does not affect the life of any component. Furthermore, as they operate at very low speeds, the hose life is not affected by the abrasive effect of the pumped product and it is practically the same as when pumping non-abrasive product.

- As there are no rotating parts in contact with the product, it is not necessary to use complex sealing systems such as mechanical seals, packing or other systems, eliminating the problems associated with certain products that are dirty or tend to polymerise.

- The pumped product does not have a lubrication function; therefore, the pump can operate for long periods under no-load conditions without suffering damage.

- As only the hose and the connections are in contact with the pumped product, it is very easy to make a corrosion resistant version, using hoses and connections that are resistant to corrosive products. A special version of the PeriBest pumps (chemical version) is available that is adapted to this type of application.