Differences between Peribest pumps and diaphragm dosing pumps

Diaphragm dosing pumps are excellent pumps for dosing a large variety of products. With their precision and onboard electronics, they have become the main option for dosing liquids.

However, due to these pumps’ design, they have a series of limitations:

- The use of valves, necessary for these pumps’ operation, is associated with problems in applications involving dirty products (containing solids); the valves become blocked, causing stoppages and changes in the dosing flow.

- In other applications with a more viscous product, the valves do not operate correctly and special valves with springs must be used. These make the pump more expensive and create accuracy and operating problems.

- This type of pump cannot evacuate air. Therefore, products that generate gases (such as sodium hypochlorite) usually cause stoppage problems.

- Diaphragm dosing pumps must always work at the same pressure as flow rates vary at different pressures. This requires the use of back pressure valves.

- The suction of this type of pump is very limited, requiring the use of foot valves, with serious problems in high suction applications.

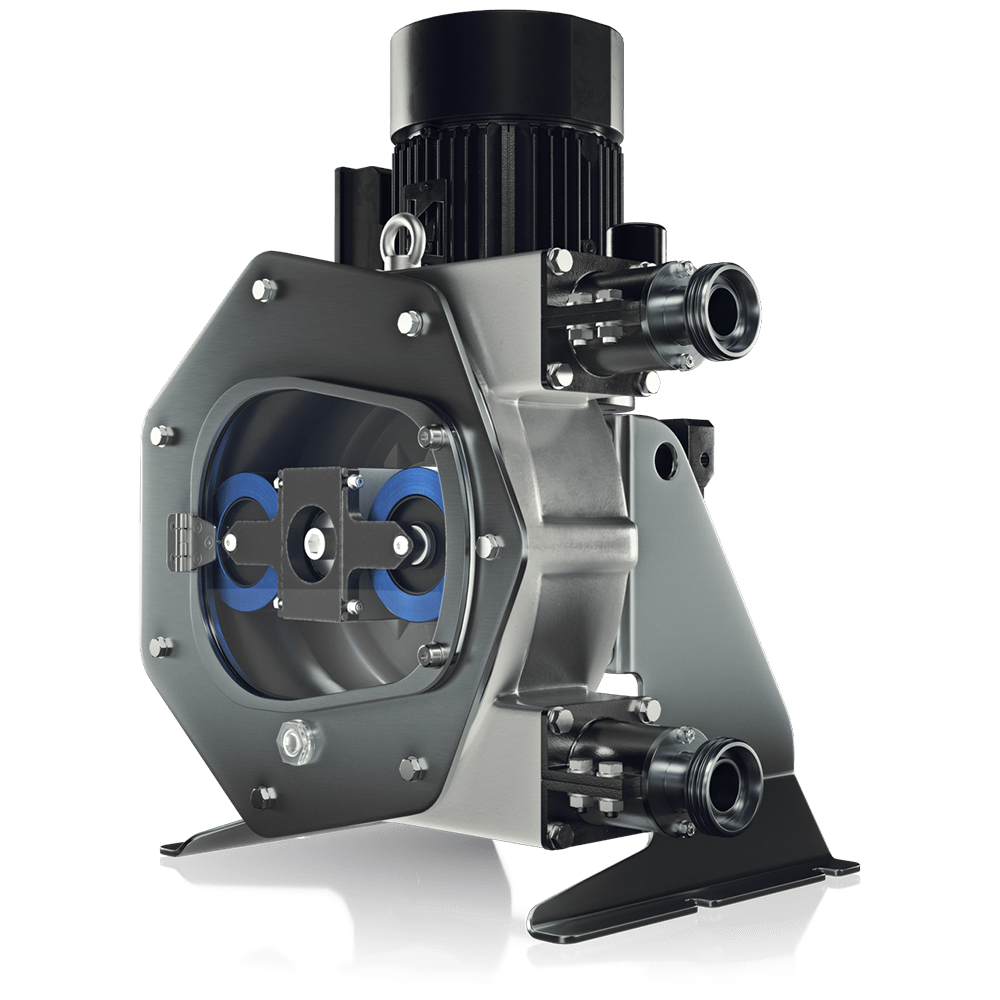

A perfect solution for applications where dosing pumps encounter problems is the PeriBest industrial peristaltic pump. The main advantages are:

- They do not require valves. Products containing solids or viscous products are no problem. PeriBest peristaltic pumps can pump and dose products with solid contents above 80% and viscosity values up to 50,000 cPs.

- Foot or back pressure valves are not required. Peristaltic pumps are capable of suctioning dry products without any problem. They do not need to be primed to operate normally.

- Neither do they require back pressure valves, as they can dose uniformly at different pressures without the flow rate being affected (it is a perfect positive displacement pump which always displaces the same capacity per revolution, irrespective of the working pressure).

- They can pump gases in the same way as liquids, enabling them to evacuate the gases produced by some products (such as sodium hypochlorite) without any problems.